Success (we are in production)

On Thursday 24th Feb. 2000, the production sampling took place at Fenton and lasted approximately one hour. The colour of glass used was Spruce Green.

Don Cunningham (in charge of Special Orders) had various shapes made as experiments, such as the rose bowl, plate, tulip/crimped vase, banana shape, etc. They also had the finisher try a tri-crimped vase by pulling up from a plate, then a tri-crimped vase by paddling down from a bowl. These items were later sold as whimsies. The experiments with the shapes confirmed that we could make a whole range of different items from the new mould and plunger.

Don Cunningham (in charge of Special Orders) had various shapes made as experiments, such as the rose bowl, plate, tulip/crimped vase, banana shape, etc. They also had the finisher try a tri-crimped vase by pulling up from a plate, then a tri-crimped vase by paddling down from a bowl. These items were later sold as whimsies. The experiments with the shapes confirmed that we could make a whole range of different items from the new mould and plunger.

|

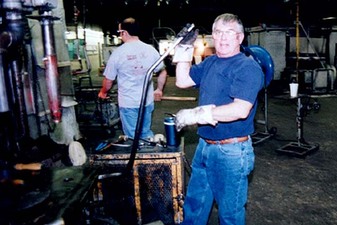

The very first gob of molten glass is cut (using metal shears) into the pristine mould. This is the very first time the mould has been used for glass, but the experienced glass worker knows just how much to cut off. |

Jimmy Reynolds at the side lever press, pressing the shape.

Right: Don Cunningham (centre) confers with the finisher on various shapes and crimps to use in the trials. |

And finally, our lovely glass.

At 11am on Thursday 23 March, 2000, production began of our commemorative in cobalt blue - the very first full run using both our new "Flowers of the World" mould and our existing "Woodsland Pine" plunger. The shape we chose was a cupped-in rosebowl - on the base plate we had the words "Williamsburg 2000" moulded. We'd done it.

At 11am on Thursday 23 March, 2000, production began of our commemorative in cobalt blue - the very first full run using both our new "Flowers of the World" mould and our existing "Woodsland Pine" plunger. The shape we chose was a cupped-in rosebowl - on the base plate we had the words "Williamsburg 2000" moulded. We'd done it.

Later......

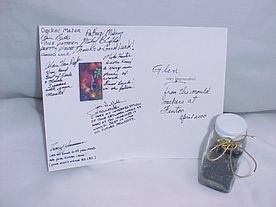

I was honoured (and speechless with delight) when Howard sent me a card signed by the Fenton mould makers when the "Flowers of the World" mould was put into use. Along with it I was also give a little bottle filled with the "viscera" - the metal pieces that are cut away during the making of the mould. Both are shown below - what memories they contain!

|

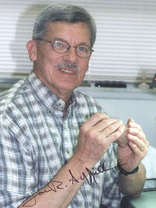

Some of the Fenton team whose skills helped to create the "Woodsland Pine" mould.Left to right:Jon Saffell, Tracy Youmans, Mike Canfield, Mike Harter and Alan Van Dyck.

Incidentally, Tracy told me that the mould weighs 82 pounds! |

|

From an idea in my head, through all those grubby pencil sketches - erased and redrawn, erased and redrawn - to a beautiful Carnival Glass commemorative.

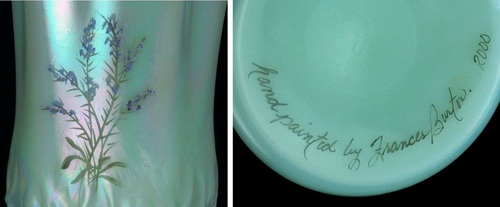

And it was all made possible through the multitude of skills along the way. Designer, sculptor, mould maker, presser and finisher - each had their part. Many of us are familiar with the hot production, as the glass is pressed, then iridised and cooled. But few of us are aware of the fascinating processes that take place prior to the actual glass production. I hope that this feature in some way goes toward an understanding of the true artistry of the mould makers - both past and present. Then I was stunned to receive another item to commemorate the occasion - this Lily of the Valley vase that the Fenton decorators had hand painted with my "Flowers of the World" design. The exceptionally talented Frances Burton actually did the painting. |

What a journey!

A Sad Footnote:

Howard Seufer sadly died in September 2017. He began working at Fenton in 1966, and his knowledge of glass, its production and the context in which it was made, was extensive. Howard was well known for his many, wonderful educational presentations, in which he combined humour with knowledge. He was also a very skilled and experienced photographer.

Howard's legacy lives on! His son, Marty, has embarked on a major tribute to Howard - the digitising of the (very many) videos that Howard made of glassmaking activities in the Fenton Factory. The first one records the making of this Woodsland Pine commemorative - a sea mist green plate.

Another sad Footnote: in mid 2015, the directors of wwwcga decided to close the club (effective March 2016).