Almost there!

The progress report from Howard in the second week of February, 2000, said the situation was that the mould had still to be fitted to a bottom plate, and be carved out for the marie (the collar base). The only thing lacking, other than a little touch up of the pattern, was to make and shape the scallop edge on the top ring (that is the piece of the mould assembly that sits between the mould and plunger and defines the top of the glass item).

In the photos below we can follow the final stages before the first glass is poured. It was getting very exciting as we could see everything coming together - and I was on the edge of my seat waiting for the mould and plunger to be used together and the first glass pieces to be made.

|

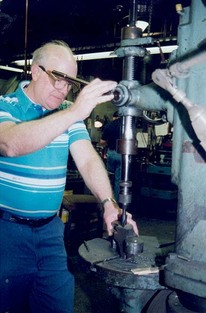

Left: on Friday 11 February, 2000, Alan was finishing the ring's scalloped edge, drilling holes in the bottom of the three sections (for the pins that guide the opening of the mould, following grooves in the bottom plate) and in testing the fit of the ring with a "wax" pour. Here, Alan is chamfering the drilled hole in the bottom of one mould section. Right: this is the mould itself with its new bottom plate, looking very bright and shiny. Note you can see all three sections of the mould - two are close together while the third is in the left foreground. |

They were ready. The new "Flowers of the World" pattern was cut on the three part mould. The existing plunger was ready for use. Top ring and base plate were all done and the test waxes showed that all parts worked together. The next stage was to actually make the glass. And that's just what Fenton did on Thursday 24 February, 2000..........

Continue the journey - Success (and production)!