Making the Mould

Stage 1: Make rough castings of a blank mould and engineer them into a complete, fitted mould assembly

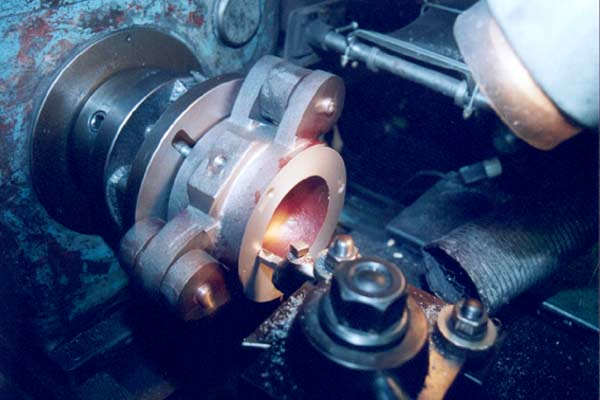

The rough castings were machined and engineered by mould makers Tracy Youmans and Mike Harter, who can be seen in this set of photos.

Stage 2: Cut the "Flowers of the World" pattern in the mould. Over to Alan Van Dyke.

|

Alan is cutting the "Flowers of the World" pattern into the mould section using a pantograph (Deckel).

Howard Seufer helped to explain: "The Deckel is a three-dimensional duplicating device. A fast rotating cutter creates the design in the iron mould, following the pattern the tracer pin makes rubbing over the master. Various sizes of cutters and tracer pins are used to progressively create more precise design details, and the final work is done by hand at the mould maker's bench. Some moulds are still started by handwork first into one section of a multiple part mould." The images below show (on the left), a close up of one of the mould sections being cut, and on the right, one section that has been completed, with another blank section waiting its turn |

Continue the journey - Problem solving