Features (and defects) of handmade pressed Carnival Glass - page 3

by Glass Engineer Howard Seufer, with additional material provided by Glen & Stephen Thistlewood

|

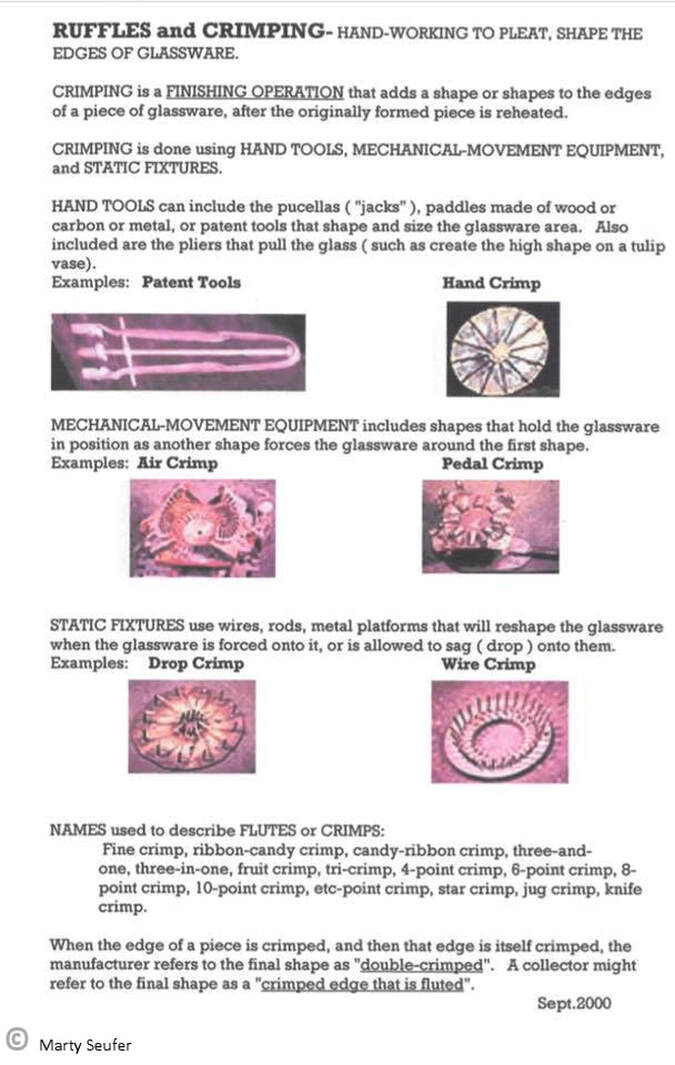

On Page 1 we looked briefly at the processes involved in making Classic Carnival Glass (making the glass batch, gathering and pressing, and hand finishing) and how pressed glass moulds worked. We also explained Features and Defects that can be found on the glass (which arose because of the techniques that were used to actually make the glass), and the main Fracture type marks. On Page 2 we explained the Non-Fracture type marks and Other Marks that are associated with handmade pressed glass. Here on Page 3 we review some of the crimping "tools of the trade" used to create the hand-finishing that makes each piece unique. |

This is a handout that Howard used to illustrate many of his excellent and extremely informative talks on this subject.

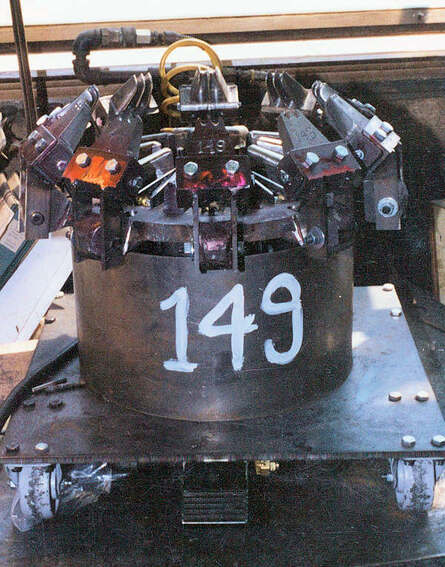

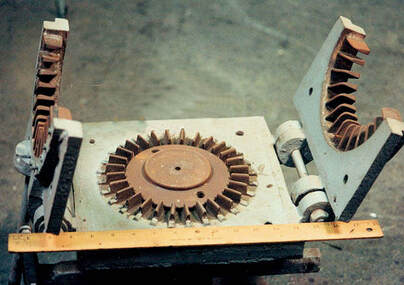

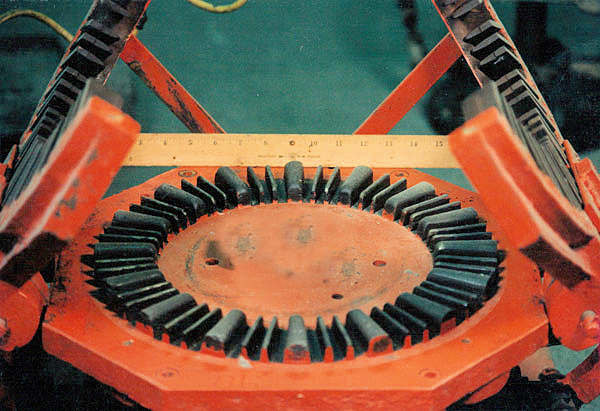

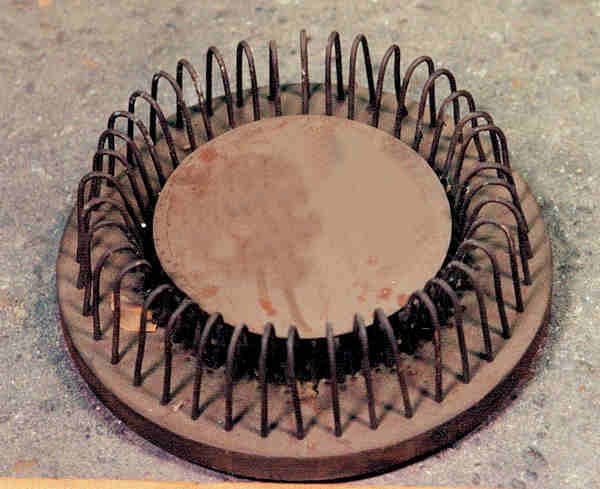

Thanks to and courtesy of the Fenton Family and Fenton Art Glass Company, we are able to show you these pictures of some of the many crimping moulds that were in actual use in the factory. Each crimp had a specific purpose: to create the actual shape of the crimp that was required, and also fit the shape and size of the item being worked on.

Hand Crimps

Hand Crimps

Various Hand Crimps.

Left: an 8 point wire Hand Crimp; centre: a 14 point wire Hand Crimp; right: an 8 point metal Hand Crimp.

Left: an 8 point wire Hand Crimp; centre: a 14 point wire Hand Crimp; right: an 8 point metal Hand Crimp.

Air and Pedal (Foot) Crimps

|

The basic operation is the same - whilst the glass is still hot and malleable, the item is placed onto the bottom section of the crimp. The upper jaws-like section is then closed over the top, and the item is pressed into shape between the two sections. The number, shape, depth of the crimps is determined by the specific crimp mould being used. The upper sections were opened and closed by hand, by a foot-operated pedal, or by compressed air. Above: a complete and very complex pneumatic crimping assembly.

|

Above: this crimp produced the "Three-in-One" crimp or "Fruit Crimp". Frank Fenton preferred to call it the "Two-and-One" crimp.

Below: a spectacular "Three-in-One" edge on an amethyst Captive Rose bowl. |

Various shapes and sizes of Drop and Wire Crimps.

Back to Page 1 of Features (and defects) of handmade pressed Carnival Glass.

Back to Page 2 of Features (and defects) of handmade pressed Carnival Glass

Further reading!

We hope this exploration of the features and defects of handmade, pressed glass has whetted your appetite to read more. Click on any of the images below.

Back to Page 2 of Features (and defects) of handmade pressed Carnival Glass

Further reading!

We hope this exploration of the features and defects of handmade, pressed glass has whetted your appetite to read more. Click on any of the images below.

|

Shear Marks are often misunderstood. They are not flaws, and they are not associated with defects on the mould or straw in the mould. They are in fact a feature of handmade pressed glass. All is explained here: Shear Marks

Magical Moulds! This page is the gateway to all our information and articles about the unsung art - and skill - of mould making. Read about making moulds in Fenton and in Sowerby. Heard about Hipkins Novelty Mould Shop? They made moulds for the major Classic Carnival Glass producers, and they were instrumental in the failure of the Millersburg factory! We also tell the story of the revival of two Dugan classics, Butterfly and Tulip and the Christmas Compote.

Thanks to unrivalled access to the master glassmakers at Fenton (arranged, photographed and documented by Howard Seufer, naturally!). Dedicated to the artists, artisans and craftsmen and their whose amazing skills, we show - step by step - how an idea for a piece of Contemporary Carnival Glass progressed from Glen Thistlewood's concept and design through to actual production.

|

This article is part of a series written specifically to answer the Frequently Asked Questions and to deal with the many Myths and Misunderstandings about Carnival Glass. Find it here: All About Carnival Glass.