Features (and defects) of handmade pressed Carnival Glass - page 2

by Glass Engineer Howard Seufer, with additional material provided by Glen & Stephen Thistlewood

|

On Page 1 we looked briefly at the processes involved in making Classic Carnival Glass (making the glass batch, gathering and pressing, and hand finishing) and we took a look at how pressed glass moulds worked. We also started to look at the Features and Defects that are to be found on the glass, which arose because of the techniques that were used to actually make the glass. We explained the main Fracture type marks. Here on Page 2 now we take a look at the Non-Fracture type marks, and Other Marks associated with handmade pressed glass. On Page 3 we look at the various crimping tools that were used in the Fenton factory. |

B) Non-Fracture type marks - they visually appear similar to crack marks.

|

FILL MARK – a very thin, very shallow line, usually found in pressed handles or looped areas. Caused by glass flowing into shape from two directions and joining; forming this line because their leading surfaces become chilled before they actually join together. |

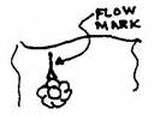

FLOW MARK – a shallow line with rounded edges found only in pressed ware. Caused by a pattern in the mould or on the plunger that interrupted the easy movement of the hot glass during pressing. |

LAYOVER MARKS – two rounded edged roughly parallel lines that look like a “railroad track”. Found only on the inside of items. Caused by the “tail” of the glass gob that was cut and dropped into the mould. The tail was laid across the surface of the glass before the shape is formed in the mould. |

|

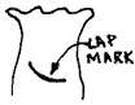

LAP MARK – an incised line with rounded edges, usually on the outside of the item. Often a curved line, it looks like the line your fingernail would make in an apple skin. Caused usually by the glass gob hitting the side of the mould before being formed, and (occasionally) by the chilling of layers of the glass gather on the punty before the gob is pressed into shape. |

PRESSURE RING – an incised line (with rounded edges) somewhat parallel with the top inside edge of a pressed item. Usually found in stem ware. Caused by glass chilling on the inside top edge then being subjected to further movement from the hot glass moving under the surface. |

SHEAR MARK – a rough, incised, rounded edge line usually on the inside of the item, especially on plates and bowls. Often, and very misleadingly called a “straw mark”. Caused by the presser’s shears chilling the glass “tail” when the glass gob is cut to size to be dropped into the mould. Read more about Shear Marks |

|

MOULD JOINT MARKS – a raised somewhat rounded line on the outside of an item; usually from the top to the bottom of the piece. Found on multiple sectioned, hinged moulds. Caused by glass forced into the mould seams, due to too much seam width, or the edges of the joints were too polished. Also due to moulds, worn by heavy use, with loose hinged joints. |

Above: a shear mark.

Left: the base of this piece has lap marks and settle waves! |

Other Marks

|

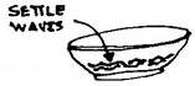

SETTLE WAVES – parallel, slightly wavy lines that form a circular shape (or part of a circle) usually found on the underside or the outside of an item.

Caused by the glass being cooled slightly whilst it was in the mould before being pressed. Most often, this is the area where the top of the glass gob sat against the mould. |

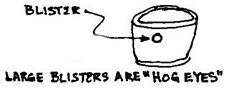

BLISTERS – a bubble in the glass that is

1/16th inch diameter or larger. Not harmful to the life of the item unless it is close enough to the surface to allow the glass to break open. Caused by air trapped in the gob when it was gathered (being picked up on the punty with a winding motion). Also can be caused by gasses trapped in the melted glass. |

SEED – a bubble in the glass that is smaller than 1/16th inch in diameter. Not harmful to the life of the item.

Caused by gasses trapped in the melted glass, and by incomplete melting of the batch. |

|

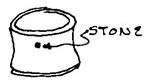

STONE – an inclusion in the body of the glass. that looks like a spot inside the glass. Can only be seen in transparent or translucent glass; can be dark, light, or optically transparent. Can be deadly to the life of the item due to the stress the stones can cause on the surrounding glass. Caused by unmelted batch materials or refractory materials from the tank or pot gathered with the molten glass. |

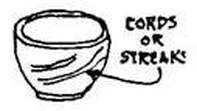

CORD, STREAKS – threadlike lines that look like patterns of different coloured or different textured strings wound around the item. Caused by variations in the glass batch and the winding pattern these variations form as the glass is wound onto the gathering rod. |

BLACK SPECKS, IRON – tiny black or brown spots on the surface of the item. Caused by iron and carbon loosened from the mould, and also from the tools used for reshaping the item. |

|

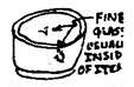

FINE GLASS – small particles of glass that adhere to the inside of an item. Caused on pressed items by the plunger crushing excess glass left in the mould which drops into the piece. Caused on blown items by the grinding of the thin “overblow”- particles fly into and stick to the very hot interior of the piece. |

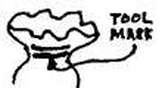

TOOL MARKS – grooves, indented lines and patterns in the areas reshaped after the initial mould shape has been formed. Caused by the tools used by the glassmakers, such as paddles, blocks, pincers and formers that were used for reshaping. |

CROOKED (RUNDOWN) – leaning, twisted and deformed shapes that differ from the intended moulded and designed shapes. Caused by reheating prior to further shaping and also from sagging after removal from the mould. |

|

ORANGE PEEL – a rough textured-looking surface that should actually be smooth. Caused by the mould surface being too cold for proper shaping of the glass surface. |

Below: the "orange peel" effect seen on the underside of the base of this bowl. Right: "tool marks" from using pincers to pull up the tip of this contemporary vase. |

COLOUR VARIATIONS – base glass colours that vary too much from the standard (intended) colour. The result is considered to be too “dark” or too “light”, too “blue” or “red”, too “cold” or “warm” etc.

Caused by the many variations in times and temperatures of glass production, and by variations in the melting and fining of the glass batch in tanks and pots. Also due to the sensitivity of the materials used in the glass formulas, including variations in the chemical used in the batch and/or the composition of any cullet that might have been included.

IMPROPER SPRAY – the surface treatment colour(s) that varies too much from the standard (intended) colour(s). The effect can appears as brown “rusty” spots, or the piece is considered to be too silver, too gold, not uniform around the piece, too shiny, too much satin look, etc.

Caused by variations in individual temperature of the piece when it was sprayed, by the time before the spray was applied, and by variations in the length of time the spray was applied for. It could also reflect when the piece was made during a glassmakers’ “turn” (that is their shift, or working hours); early in a turn and the spray may be applied more liberally, but later in a turn, supplies may have been getting low, and the spray was applied more carefully (or even diluted!)

There are also other features that can be recognised as evidence of handmade glass, such as variations in the thickness of applied handles, or irregularly shaped crimped edges. They all add to the infinite variety and individual charm of a piece of Carnival Glass. Uniformity came later, when in some glass making companies, handmade techniques gave way to more machine oriented production-line processes, and in Contemporary Carnival Glass production where quality control techniques became more prevalent.

Continued on Page 3 - the crimping "tools of the trade" used to create the hand-finishing that makes each piece so unique.

Back to Page 1 of Features (and defects) of handmade pressed Carnival Glass.

|

Shear Marks are often misunderstood. They are not flaws, and they are not associated with defects on the mould or straw in the mould. They are in fact a feature of handmade pressed glass. All is explained here: Shear Marks

Magical Moulds! This page is the gateway to all our information and articles about the unsung art - and skill - of mould making. Read about making moulds in Fenton and in Sowerby. Heard about Hipkins Novelty Mould Shop? They made moulds for the major Classic Carnival Glass producers, and they were instrumental in the failure of the Millersburg factory! We also tell the story of the revival of two Dugan classics, Butterfly and Tulip and the Christmas Compote.

Thanks to unrivalled access to the master glassmakers at Fenton (arranged, photographed and documented by Howard Seufer, naturally!). Dedicated to the artists, artisans and craftsmen and their whose amazing skills, we show - step by step - how an idea for a piece of Contemporary Carnival Glass progressed from Glen Thistlewood's concept and design through to actual production.

|

This article is part of a series written specifically to answer the Frequently Asked Questions and to deal with the many Myths and Misunderstandings about Carnival Glass. Find it here: All About Carnival Glass.