Mould making - the Sowerby way

Moulds and plungers are complicated (and expensive) pieces of technical and mechanical wizardry. They are the essential part of pressed glass (and by definition, Carnival Glass), and the master craftsmen who made them are the unsung heroes of the pressed glassmaking world! We know so much about the glassmaking companies, like Fenton, Imperial, Sowerby etc., but we know much less about who made the moulds!

Here we have a first-hand account from Adam Dodds - he worked at Sowerby's during the late 1940s and early 1950s as their Glass Technologist. He kindly gave us his comments on what he recalls about mould making at the factory during that era, which would be little changed from when they were making moulds for their Carnival Glass.

Here we have a first-hand account from Adam Dodds - he worked at Sowerby's during the late 1940s and early 1950s as their Glass Technologist. He kindly gave us his comments on what he recalls about mould making at the factory during that era, which would be little changed from when they were making moulds for their Carnival Glass.

|

Adam Dodds:

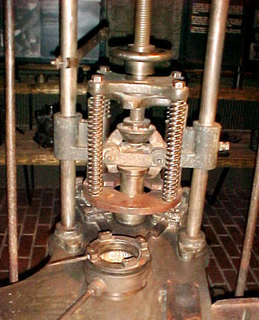

"In the absence of a copying machine (the pantograph), our mould makers at Sowerby's had to do the same thing directly on to the cast iron mould for the entire pattern, using hand tools. Also, at Sowerby's we did not have the early stages of wax casts and plaster moulds that modern glassmakers have now. Our mould components were made of chill cast grey cast iron, cast in sand moulds (in our own one man foundry). There was no detail whatever and every surface was rough. The approximate shape and size would be determined from whatever model or drawing had been provided. A great deal of machining took place of every surface other than what was to become the outside of the mould which would never contact glass or other bits of the mould. Milling, turning, shaping, drilling, reaming and hand fitting were all involved in the process. Only after all this would the mould cutter be involved. The surface to be cut was lightly copper-coated and the intended pattern would be accurately marked in pen and ink. That might involve geometry (eg star bottoms) or pure art. Modelling clay played a big part both to check progress ("take a clay") or possibly to take an impression from whatever model might be available. Hammer, chisel, riffler files and emery cloth were the only tools." |

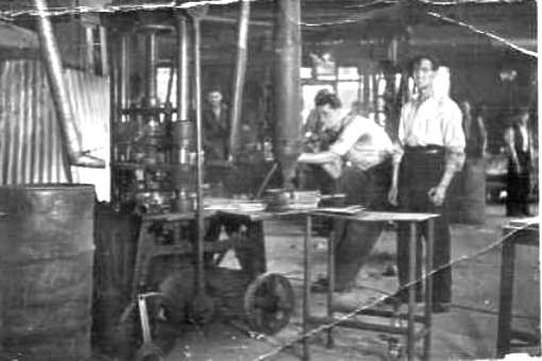

What Adam describes above is, of course, how it was done during the Classic Carnival era too. The side lever press shown in the above picture of Sowerby's press shop would be entirely familiar to the pressed glass makers at, say, Fenton in the early 1900s, and the Hipkins Mould Company (who made many of the Carnival Glass moulds and plungers) and others, would have used the techniques much as Adam describes above.