Stephen Hipkins - Master Mouldmaker

Stephen Hipkins was a Lancashire lad by birth. Born in England in 1841, he emigrated to the USA when he was eight years old. His dad was a blacksmith and Stephen followed in his footsteps, working with metal, and becoming apprenticed in an iron foundry when he was just fourteen. After that he worked on the railroads for a while as an engineer (specifically a “locomotive machinist”) before going it alone and setting up his own business.

|

So, what has a locomotive machinist on the Ohio Central Railroad got to do with Carnival Glass? Simples! Stephen Hipkins’ business was the creation and design of metal moulds for the glass industry. He didn’t make the transition from railroad engineer to mould maker in one easy jump though – Hipkins actually spent several years learning the skills and techniques at various glass plants (Belmont, Hobbs Brockunier and Buckeye) before eventually setting up his own mould shop. Three of Hipkins’ sons started working in their father’s mould shop as soon as they reached their teens (he had ten children in all). The family was also friendly with another Englishman, Harry Northwood; according to author Minnie Watson Kamm, when Harry brought his new bride, Clara, to America in 1882 they stayed at Stephen Hipkins home until they could find a place of their own. Hipkins established his company, the Hipkins Novelty Mould Shop of Martins Ferry, in 1884. The company quickly gained itself a good name for both design work and mould cutting - moulds were cut by hand with a hammer and chisel. |

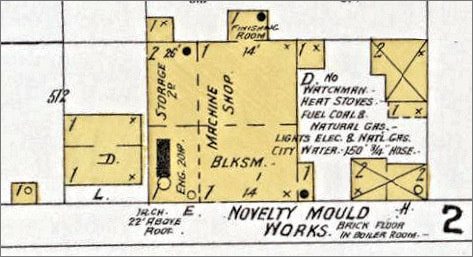

Sanborn Fire Insurance Map, 1900, showing the Novelty Mould Works

owned by Hipkins, in Martins Ferry, Ohio. Public Domain |

|

Here’s what “The Wheeling Daily Intelligencer” wrote in 1886: “By hard work and perseverance this business has grown to be the largest of the kind in the valley outside of Pittsburgh. The reputation of his goods is wide spread”. Kamm wrote that Stephen Hipkins and his eldest son George, concentrated on design work while sixteen “highly trained artisans” cut the moulds. Kamm also notes that George Hipkins was taught by Harry Northwood to etch and engrave glass and there was clearly a strong bond between the two families as not only did George Hipkins become a shareholder of Northwood’s firm, he also acted as pall bearer at Harry’s funeral. |

Given the closeness of the two families, it would not be surprising if Hipkins supplied some of his best, and most artistic moulds to Northwood, such as Rose Show and Peacocks shown here. Speculation yes, but it's quite possible.

|

Another of Hipkins’ big customers was the Fenton Art Glass Company. Fenton began in Martins Ferry in 1905, not far from Hipkins mould shop and their custom continued when Fenton moved to Williamstown.

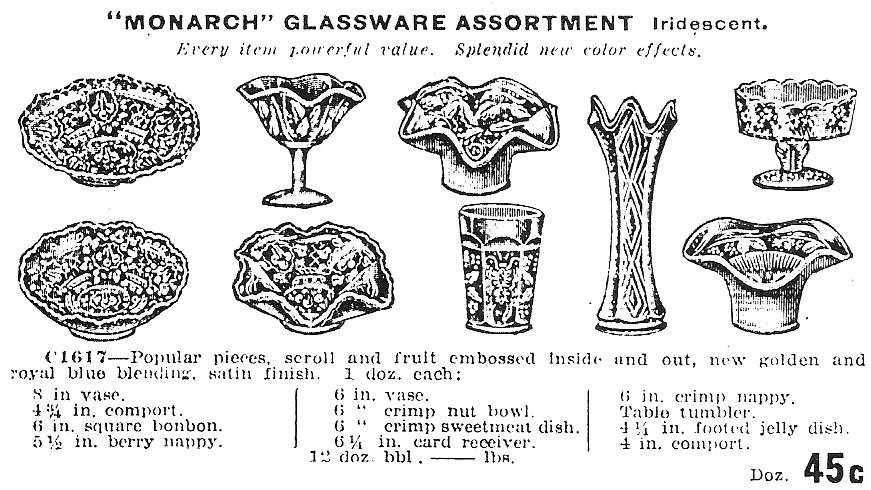

Some years ago we were privileged that the late Frank M. Fenton gave us access to study Fenton's archives. In them, we came across cheque book stubs dating back to the early 1900s. The cheques were drawn on the German Savings Bank, Martins Ferry, Ohio (which was set up in 1902) and they were all made payable to either S. Hipkins or Hipkins Novelty Mould Company. Here are some examples of what we found: a stub dated 1908 was for “tumbler moulds” and was for $63. In 1909 a stub for $211.88 was for “vase moulds” and in 1911, $70 was paid out for “an oval mould”. On the right is a contemporary ad from Butler Brothers, showing a Fenton "Monarch" assortment. Note the relative cost of the moulds bought from Hipkins and the wholesale price of the Carnival Glass! |

|

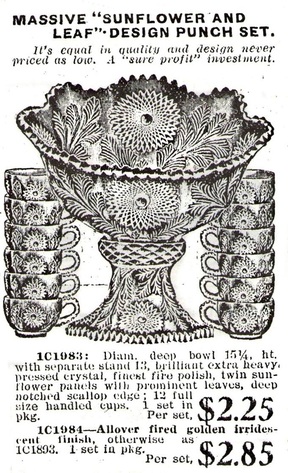

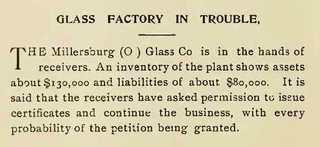

The 1909 Butler Brothers’ ad on the left shows one of Millersburg’s first patterns, Hobstar and Feather, in the form of a massive punch set. The mould for this was almost certainly made by Hipkins Novelty Mould Company. The pattern was originally called a “Sunflower and Leaf” design; it was only later that the name Hobstar and Feather was subsequently (and arguably, erroneously) given to the pattern by Marion Hartung, who misinterpreted the stylised sunflower and leaf motifs. For Millersburg, buying moulds from Hipkins was both a positive and a negative. It’s known that the moulds for many of the early Millersburg lines were made by Hipkins, however, John Fenton (owner of Millersburg Glass) clearly was not in a hurry to pay Stephen Hipkins for them. And it was this continuing non-payment that was almost certainly the beginning of the end for the short-lived Millersburg Glass Company. In August 1909, just four months after Millersburg had begun operations, Stephen Hipkins began legal proceedings against the company for the non-payment of “an extensive line of moulds with which the firm had made its first products” (“Millersburg Glass”; McGee). The case proceeded very slowly, and two years later a verdict was awarded in Hipkins’ favour. By then, other creditors (around two dozen in fact) had also taken legal action against Millersburg Glass and their eventual demise was in sight. The above extract from the 1911 Crockery & Glass Journal gives a fascinating insight into the slow, yet steady collapse of the Millersburg Glass Co. Read more about their downfall here.

|

Look at many of the beautiful and familiar Classic Carnival Glass patterns and you will perhaps think of Fenton, Northwood, Millersburg and so on. But the name behind the design and creation of a good number of those familiar patterns needs a name too: that name is Stephen Hipkins.