A Brockwitz Factory Tour, 1928

With grateful thanks for their invaluable assistance in this article, to Bob Smith (Boston, USA), The Coswig Museum (for a copy of the

Brockwitz Glass Factory's 25th. Anniversary Jubilee publication), and Dr. Bernhard Mossner, Director of Public Relations, Coswig.

Brockwitz Glass Factory's 25th. Anniversary Jubilee publication), and Dr. Bernhard Mossner, Director of Public Relations, Coswig.

Our research in the late 1990s turned up a fascinating extract from the July 1928 British Pottery Gazette. It was in a report by senior glass workers who had gone on a fact finding trip to Germany.

The arrival at Brockwitz

"On arrival at Dresden, the old and historic capital of Saxony, early in the forenoon of May 16, motors were found to be in readiness to convey the party to Brockwitz, a glass-manufacturing village situated on the banks of the Elbe not many miles from the well known porcelain manufacturing town of Meissen. To make the trip the more interesting, the journey outwards and homewards was made a kind of circular tour; the left bank of the Elbe was followed for some fifteen miles from Dresden to Meissen, the river was then crossed by the bridge near the Albrechtsburg Castle, which stands 160 feet above the city on Castle Hill, where the original Dresden china was made from Bottger's recipe, and the right bank of the Elbe was then followed as far as Brockwitz, the journey subsequently being continued there from back to Dresden."

The arrival at Brockwitz

"On arrival at Dresden, the old and historic capital of Saxony, early in the forenoon of May 16, motors were found to be in readiness to convey the party to Brockwitz, a glass-manufacturing village situated on the banks of the Elbe not many miles from the well known porcelain manufacturing town of Meissen. To make the trip the more interesting, the journey outwards and homewards was made a kind of circular tour; the left bank of the Elbe was followed for some fifteen miles from Dresden to Meissen, the river was then crossed by the bridge near the Albrechtsburg Castle, which stands 160 feet above the city on Castle Hill, where the original Dresden china was made from Bottger's recipe, and the right bank of the Elbe was then followed as far as Brockwitz, the journey subsequently being continued there from back to Dresden."

|

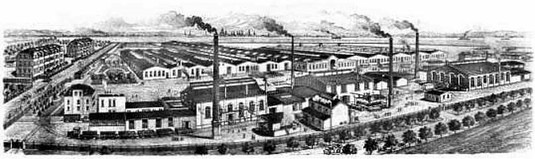

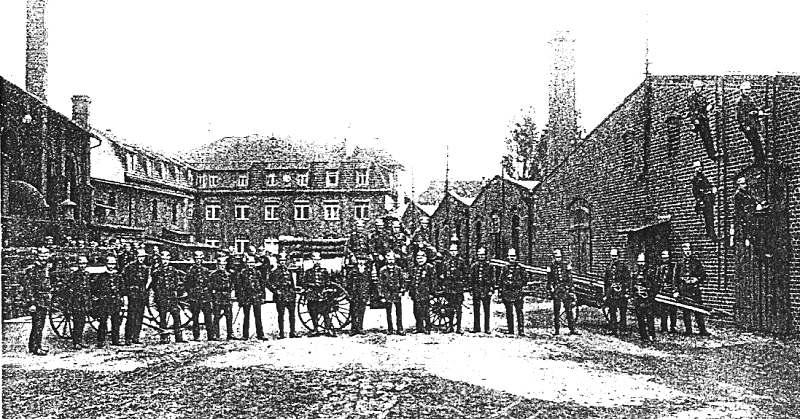

The narrative continued to describe the Brockwitz glassworks and the processes carried out there. Below are several extracts from the 1928 text. “At Brockwitz it was a pleasure to the party to inspect from beginning to end a glassworks known as the Aktien Gesellschaft Brockwitz, an important concern employing many hundreds of hands and manufacturing a big range of inexpensive commodities in pressed table glass. The Brockwitz factory, which was established in the year 1903, and has thus recently completed its first quarter of a century of glass making, has, it would seem, shown continuous growth and development from the commencement until the present time … It is a factory which transacts a big home trade and also a huge trade with overseas markets. Its methods reveal briskness and economy at every point, and it was, therefore, a particular privilege to be allowed to see right over the works, from the furnaces to the showroom.” |

Points of Special Interest

“The following are a few points of special interest which were noticed in visiting the Brockwitz factory.

“The following are a few points of special interest which were noticed in visiting the Brockwitz factory.

|

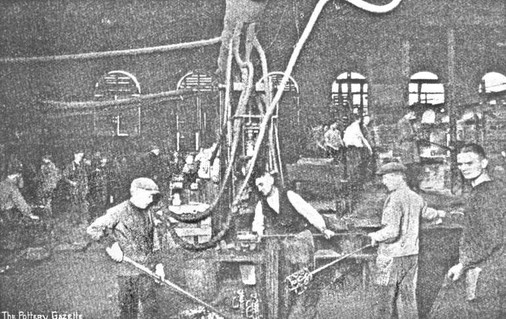

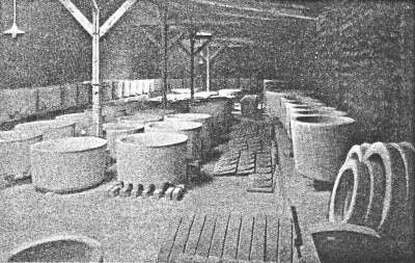

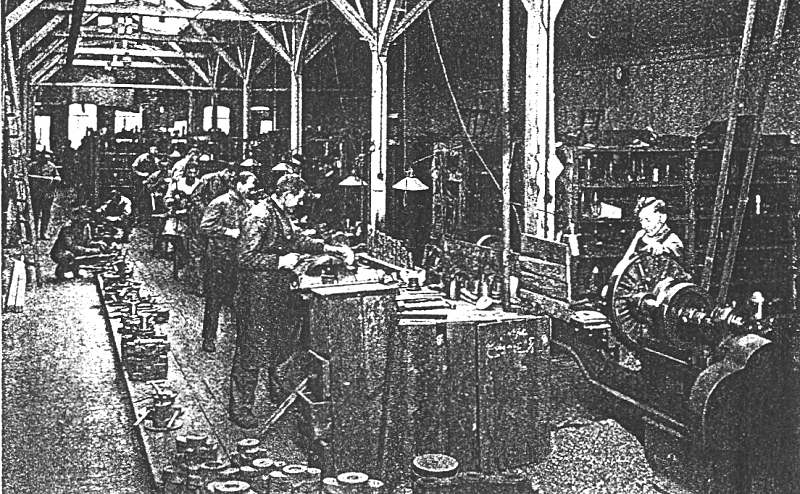

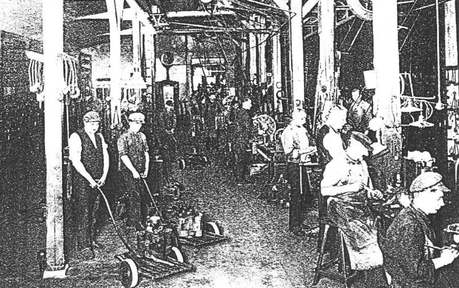

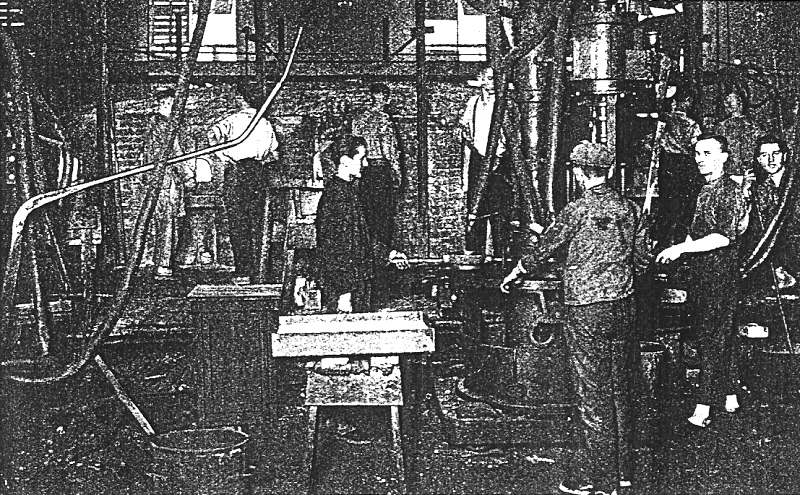

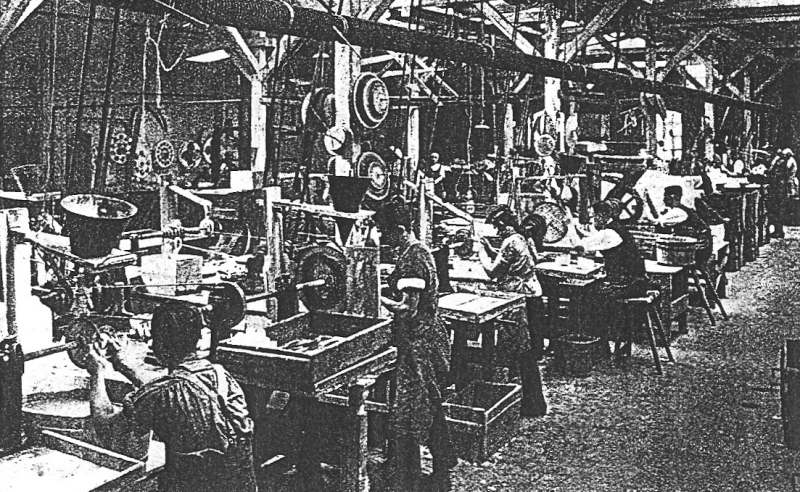

In the first place, the firm make all their own melting pots, and they have a large and very well-equipped pot room, where pot-making appears to have been reduced to a commercial science. They also make all their own moulds and have a huge engineering shop employing an army of engineers and mechanics. In visiting this mould making department it was observed that many of the moulds are cut by an electrolytic process and coated with a layer of chromium to guard against a too rapid wearing of the sharp edges, and to ensure thereby a finished article of better quality." Right: The Pot Room - a vast supply of melting pots ready for use. Below left and right: The Mould Shop - a huge operation! It's not surprising given that Brockwitz's 1928 "Musterbuch" (catalogue) was 134 pages and averaged about 10 different items on each page. The pictures below show a large number of partly and fully assembled moulds, so it;s likely these workers were also re-furbishing moulds. |

Glass Pressing

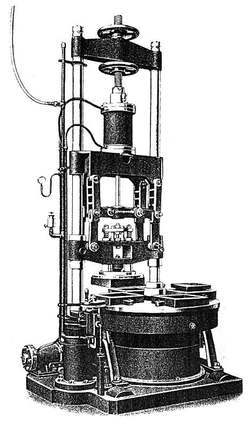

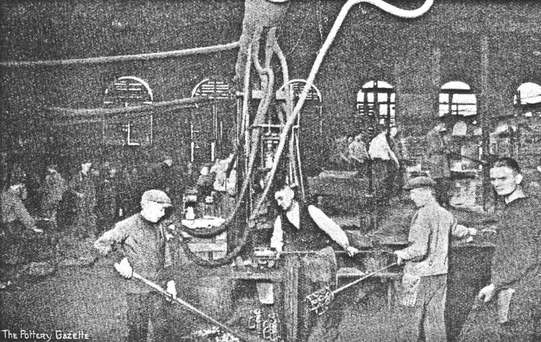

The report continued: "In the glass-houses use is extensively made of semi-automatic pressing machines, a compressed air system greatly minimising the heaviness of the labour that would otherwise have to be encountered in the levering of the larger pieces. The speed of working at the furnaces was high - much

The report continued: "In the glass-houses use is extensively made of semi-automatic pressing machines, a compressed air system greatly minimising the heaviness of the labour that would otherwise have to be encountered in the levering of the larger pieces. The speed of working at the furnaces was high - much

|

higher, we should imagine, than is the normal experience in English glassworks. In the case of one automatic press there was a revolving table containing a number of different moulds, and pressing was proceeding in half a dozen of these simultaneously; it seemed to be a case of mass production, but adjustable for small orders”.

Pictured on the right is a glass pressing machine and it is clear that there are four moulds on the revolving table under the plunger. |

Finishing off the glass

|

The report went on to say:

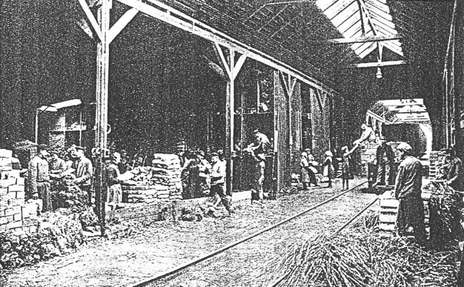

“From the furnaces the pressed glasswares are put through a fire-finishing process. A moving belt of flexible wire conveys the articles over the hot zone, and they are then tipped off on to a belt which runs away at right angles and conveys them to the annealing lehr. This was an arrangement which was considered to be a real time saver. Several presses were switched up to a common lehr, and a youth was engaged at the lehr mouth working furiously at placing the articles into position. To get a better ultimate finish the bottoms of all articles, star-pressed or otherwise, are ground and polished, and a big staff of women grinders was seen to be engaged on this work; a whole shop was, in fact, devoted to grinding and polishing alone.” Shipping and Despatch Glass factories rely on good transport links, both for the supply of bulky raw materials, and also for getting their (heavy) glass products out to market. |

Brockwitz was clearly fully integrated and the picture below shows a railway line coming right into the factory. It looks like the inward goods were unloaded on the left, and the finished items were packed and loaded on the right.

Showing Off!

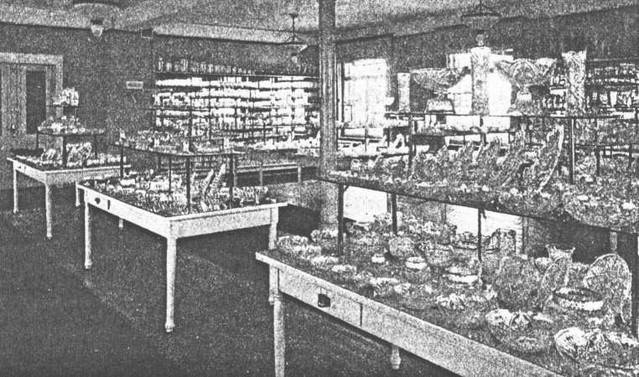

Naturally, Brockwitz was undoubtedly proud of the glass they produced and they had a large and impressive showroom on site to display it to best advantage.

Naturally, Brockwitz was undoubtedly proud of the glass they produced and they had a large and impressive showroom on site to display it to best advantage.

|

The factory visitors remarked that: “It would be impossible in the space at our disposal to give a full description of the types of wares being produced at the Brockwitz factory, but it was obvious, in viewing the contents of the showroom at the completion of the tour of the works, that in addition to a big trade with Great Britain, the requirements of the Eastern markets are specially catered for, the wares being for the most part inexpensive, and simulating goods produced by much more expensive processes. It did not call for shrewd observation to notice that the imitation of cut and engraved patterns was being very successfully carried on as the result of simple pressing and polishing. Some of the designs were quite attractive, and all seemed to aim at capturing the more popular markets.” It’s hard to make out the details on such an old photo, but we are certain that we can see a number of Curved Star items on the display tables in the foreground. On the lower part there appear to be some very large bowls. |

|

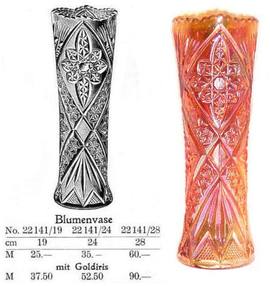

The catalogues show that the Curved Star (aka Zurich) bowls went up to around 11” across, so that’s surely what is shown there. On the middle shelf it’s possible to discern a series of plates in increasing sizes; the catalogue shows the Curved Star range plates from 6” to 12”. On the right is a (rather fuzzy) enlargement of the top shelf; we believe the items shown are (left to right) a large Curved Star bowl on an upturned stemmed sugar (making a centre-piece), a Curved Star cylinder vase, the one-piece Curved Star fruit dish and another Curved Star cylinder vase. |

Above: A Curved Star fruit dish - catalogue image and one in blue (courtesy of Michael O'Brien),

and a Curved Star cylinder vase in marigold with catalogue image.

and a Curved Star cylinder vase in marigold with catalogue image.